BlastFlow Siberian Modular VGA Waterblock

September 1, 2007 | 04:34

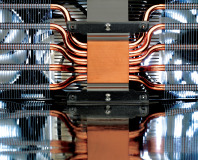

There’s no ice in Siberia...

The main portion of the block is machined from copper and the insides are shaped rather like a Maltese cross. Inside the cross shape there are various waves that increase the surface area and help to increase turbulence inside the block.According to BlastFlow, the base is less than 1mm thick at its thinnest point. Looking at the design of the internals from a broad perspective, you would imagine that there would be a lot of "dead spots," or places that weren't cooled because fluid didn't circulate well. It was a question we put to Mr. Chobanu and he said he felt the same way, but after months of experimentation, it was what worked.

He then elaborated a little and said he showed the design to a fluid dynamist in order to understand why his design worked so well, and even he wasn’t able to gauge how the design was so effective. Vadim said that the physicists words were along the lines of “this shouldn’t work, but somehow it does.”

Both the top of the block and the cooling plate that cools the rest of the card’s hot components are machined in aluminium and then anodised black. The top of the block is secured to the copper base with 13 screws and is sealed with a rubber O-ring.

The cooling plate simply fits snugly under the GPU block and is designed so that the block not only gives a good contact with the GPU core, but also clamps it down onto the memory chips. Combined with the five screws that hold the cooling plate onto the graphics card, that’s more than enough to keep everything secure and, more importantly, get a good contact on everything that it needs to. The difference between this and the Danger Den is that this is very simply cut to size, whereas the DD has clearly spent a lot of time on the C&C machine getting all the grooves and pits individually done in the block as a whole. The Danger Den block looks better, but the Vadim design works just as well at providing contact and still gives it its universal nature.

MSI MPG Velox 100R Chassis Review

October 14 2021 | 15:04

Want to comment? Please log in.